Nowadays energy-saving indexes become basic among competing equipment manufacturers, so RUE works «Mogilevliftmash» began to manufacture energy-saving elevators LP-0463BE and LP-0401BE in 2008.

Nowadays energy-saving indexes become basic among competing equipment manufacturers, so RUE works «Mogilevliftmash» began to manufacture energy-saving elevators LP-0463BE and LP-0401BE in 2008.

Basic distinction of these lifts is the application of the main drive speed controller and drive of cabin doors. Speed controller gives significant saving of the electric power (about 34,7%) and ensures smoothness of lift traffic. The average value of power consumption for double-speed drive is 3,54 kW/h, for main drive speed with speed controller is 2,31 kW/h.

Energy-saving elevators are widely applied for replacement of morally and physically worn elevators equipment. The installation of energy-saving elevators needs no cabin guides and counterweight or fixation parts. It allows saving up to 30% from the funds of equipment production and transportation. The period of elevator’s installation and commission compound up to 2-3 weeks.

Thus all expenses reduction for a new elevator production, transportation and reinstallation will compound up to 50% .

The advantages of energy-saving elevators.

The advantages of energy-saving elevators.

1. The smoothness of cabin’s acceleration and braking makes transportation more comfortable for passengers and reduces noise and vibration in dwelling house.

2. The weight of elevator’s winch is reduced due to flywheel absence.

3. Winch life is increased due to transient smoothness, which reduces burden on worm-and-worm gear and reduces brake shoes wear.

4. The limitation of starting current for driver reduces energy consumption during start-ups up to 2-3 times, reduces driver’s heating temperature which allows expanding its life.

5. In energy-saving elevators main drive speed is installed. It has lower weight, dimensions and prize in compare to traditionally applied double-speed drive.

The main features of LP-0463BE and LP-0401BE elevators.

1. The main drive winch is manufactured on the basis of the new incline reducer with the spacing on centers is 125mm and improved exploitation characteristics. The main drive speed equipped with frequency convertor is installed in winch. This innovation makes elevators movement smoother and more comfortable. The winch is equipped with brakes of two-system deceleration. It allowed to improve passengers safety and reduced brakes work noise. Due to transient smoothness, which reduces burden on worm-and-worm gear and reduces brake shoes wear. 160 mm spacing on centers winch weight is about 600 kg, the winch weight is 360 kg. The volume of oil flooded in reducer is twice reduced.

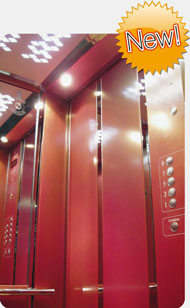

2. The cabin is delivered to the place in disassembled long-pitch state and consists of coupe and carcass.

Carcass consists of:

- upper landing doors beam with safety catchers and weigher;

- lower landing doors beam;

- bearing riser of cabin’s carcass.

Cabin’s coupe is manufactured in anti-vandal variant and includes:

- immobile floor;

- modular ceiling;

- cabin’s coupe walls, assembled of standard modules, intermodule and portal columns;

- сontrol board – complete module, in which basic electric equipment of cabin is installed.

3. Shaft doors are equipped with shaft door locks in strict conformity with international certification standard CE.

4. Elevator’s electric drive and automatic equipment are produced on the basis of elevator’s microprocessorcontrol panel in strict conformity with PUBEL requirements.

Buy energy-saving elevators and save your money!