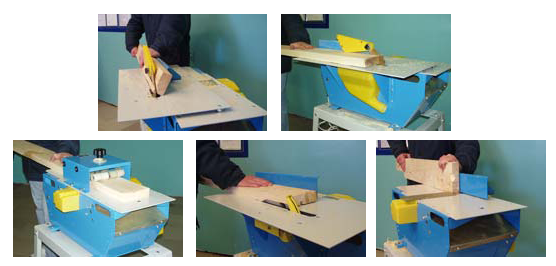

Woodworking machines are designed to perform the following types of timber machining: dressing (with the presser) of the workpiece by flat surface at working surface machining per run of up to 200 mm and workpiece thickness of max 50 mm;

- dressing at angle and by edge;

- sawing lengthwise and crosswise the fibers;

- length cutting at an angle of 0 to 45є

- groove milling and quarter cut by a disk milling cutter.

• Basic technical data of woodworking machines IE-6009A2.1-02, IE-6009A4.2-02

The woodworking machines produced today have high-powered motors.

Considerable attention was focused on the woodworking machines usability and safety:

- Thermoswitch, which protects the motor from overheating, was introduced in the IE -6009A2 machine motor winding;

- For the IE-6009A2.1-02, IE-6009A4.2-02 machines automatic switch, which protects machines from overload and ensures fast shutdown, was introduced.

- These woodworking machines are equipped with the handles.

- The saw and disk cutter have the housing; the disk cutter housing is closed when the blank passing the cutting area.

- The saw housing has a nipple for the dust-trapping unit connection (such as vacuum cleaner) and a nipple for the sawdust bag attachment.

- During the dressing an inactive part of the porcupine cylinder is closed by the special housing. The motor power supply and control - a single-phase alternating current, voltage rating 220V, frequency 50H